A New Bicycle

Mr. M. Pedersen of Dursley, with that ingenuity for which he is known, has recently constructed a safety bicycle of remarkable character. It's weight is only nineteen pounds and the maker has tested the strength in an extraordinary way, he having ridden it up Whiteway (a very steep hill) in Dursley, England.

The Dursley Gazette

21st October 1893.

There is very active FACEBOOK group.

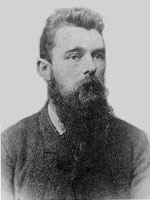

I created this site to spread the knowledge of, first and foremost the The Pedersen Cycle, but also to give you a chance to get some knowledge of the inventor Mr. Pedersen, whom in many ways was a very special man, one of his kind.

Mads Rasmussen, DK

Mr. Pedersen's bicycle is one of the most beautiful bicycles ever invented, with regards to harmony, strength and lightness in the frame.

It might look a bit different than other bicycles of today, but it's only a coincidence that the "normal framed" bikes aren't Pedersen cross framed bicycles.

"After more than a century, Pedersen's design continues to be an example of unique craftsmanship in a world of mass-produced convention. Pedersen bicycles are a link to the past, when cycling brought independence and freedom of movement, when quality was apparent, when details mattered, when style was beautiful."

(Quote Henry Meudt)

If Mr. Pedersen had had the same skills as a businessman as he had as an inventor, the Pedersen bicycle would have been the most widespread bicycle of all. But Mr. Pedersen was unfortunately a very poor businessman and he died a poor man.

His bicycle became a collectors item instead of a most commonly used bicycle.

(Editors remark)

Ingenious Mikael Pedersen.